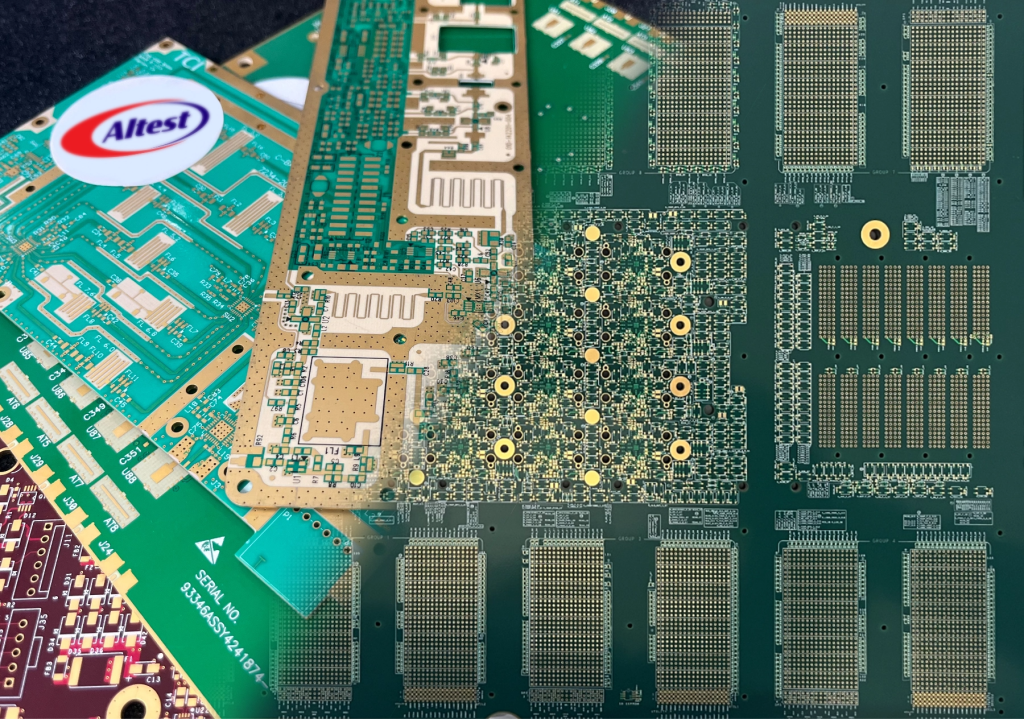

Fabrication

Altest’s PCBA capabilities paired with the highest quality PCB boards ensure the exceptional end-products we deliver.

PCB

- Multilayer up to 60+ layers

- Embedded passives

- Heavy copper up to 10 oz.

- Over 50 UL approved laminates

- Thickness up to 0.450"

- Thin core dielectrics

- Dimensions up to 30" x 54"

- Mixed dielectrics

RF & Microwave

- High frequency/bandwidth designs

- Dielectric foam

- Planar and screened resistors

- Conductive paste

- Dimensions up to 24” x 48”

- Mixed dielectrics (hybrids)

- Plated cavities

- Formed (conformal) PCBs

- Optical machining

HDI

- Up to 12L “any layer” stacked uVia Structure

- 1.6 / 2.0 mil / space

- Wide material and surface finish selections

- 3/7 mil uVia / Pad size

- 14 mil, 6L ultra-thin structure

- Embedded, distributed and discrete passive components

- 0.4 mm pitch BGA with 2 traces fanout

Thermal Management

- Passive and active designs

- Buried metal core constructions

- Externally mounted heatsinks

- Epoxy and B-stage films

- Thermal & conductive bonding

- Aluminum & copper base materials

Flex & Rigid-Flex

- Type 2, 3 and 4 (double-sided, multilayer and rigid-flex)

- Epoxy fillet Bikini cut, bookbinder and loose-leaf construction

- Acrylic, epoxy and adhesive-less polyimide flex materials

- 30+ layers

- Dimensions up to 24" x 48"

- Combination surface finishes

- Over 50 rigid material options

- Thickness up 0.300"

IC Substrate

- 2,4,6 Layers (2+2+2 stacked via)

- BT material

- Type: SIP,CSP,BOC & FC package

- Flip chip C4 pad

- Fine trace width/space 25/25um

- Thin board: 130um(2L), 170um(4L)

- Wire bonding (ENEPIG, Soft gold, Hard gold)

Mixed Materials

- Passive and active designs

- Buried metal core constructions

- Externally mounted heatsinks

- Epoxy and B-stage films

- Thermal & conductive bonding

- Aluminum & copper base materials

- Various surface finishes

Multi Layer

- Acrylic, epoxy and adhesive-less polyimide flex materials

- Over 50 rigid material options

- Thickness up 0.300”