Altest assembly lines are geared towards flexibility!!!

Altest Multi-Flex assembly lines allow us to work on any size board without sacrificing speed and reliability.

Schedule a tour and let Altest show you why we are the top PCBA Manufacture in Silicon Valley.

SMT (Surface Mount Technology)

Surface Mount Technology (SMT) is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB).

An electrical component mounted in this manner is referred to as a surface-mount device (SMD).

Solder Paste Screen Printer

With the latest Solder Paste Screen Printer, we are capable to print larger boards to accommodate our customer requirements.

- Large Board Example: 850mm x 610mm (33.46" x 24")

- Quick Change --> Less than 2 minutes change over setup time

- Automatic Stencil Cleaner

- Print Accuracy +/- 25um

- Fixed and Interchangeable Frame Possible

SPI (Solder Paste Inspection)

- Our 3D Solder Paste Inspection Machine provides Real-Time solder inspection.

- This eliminates critical shadow problems while enhancing productivity and speeding up the production process.

- It ensures the correct deposition of solder paste on the board without faults and helps achieve a Zero-Defect from the solder print process.

Altest’s New SMT Pick-n-Place Lines

- ASM X-Series by Siplace

- Mycronic ? 200SX, 300SX (Single Head), 300DX (Dual Head)

- High Speed Placement Twin Heads

- High speed placement with Linescan Vision System-4K Resolution

- Board Size: 850mm x 610mm (33.46” x 24”)

- Board Size: 482mm x 584mm (19" x 23")

- Component Placement: 01005 Size to 200mm x 125mm Size

- Component Placement: 01005 Size to 63mm x 63mm Size

- Component Placement Pitch: 0.3mm

- Component Placement Pitch: 0.3mm

BTU International Reflow Oven / 12 Zone

- Tin Lead & Lead-Free Capability

- 12 Heating Zones / 2 Cooling Zones

- Maximum Temperature Rating (all Zones) 350 C

- Nitrogen Installed (99.99% Pure Solder)

AOI (Automated Optical Inspection)

- AOI (XL / 3D) provides the quick and precise inspection required to ensure that the product is of high quality without any manufacturing defects.

- 3D Inspection

- Board Size: 850mm x 610mm (33.46” x 24”)

3D X-Ray

- The 3D X-Ray tool enables us to inspect components that may not be visually accessible from the top and/or bottom.

- Detect Solder Bridge’s, Cold Solder and Voids

Thru Hole

- Components that need to be Thru Hole are inserted onto the project and submitted to the Wave Soldering Department.

- Any size and tolerance of a thru hole component can be inserted to match your PCB Design requirement.

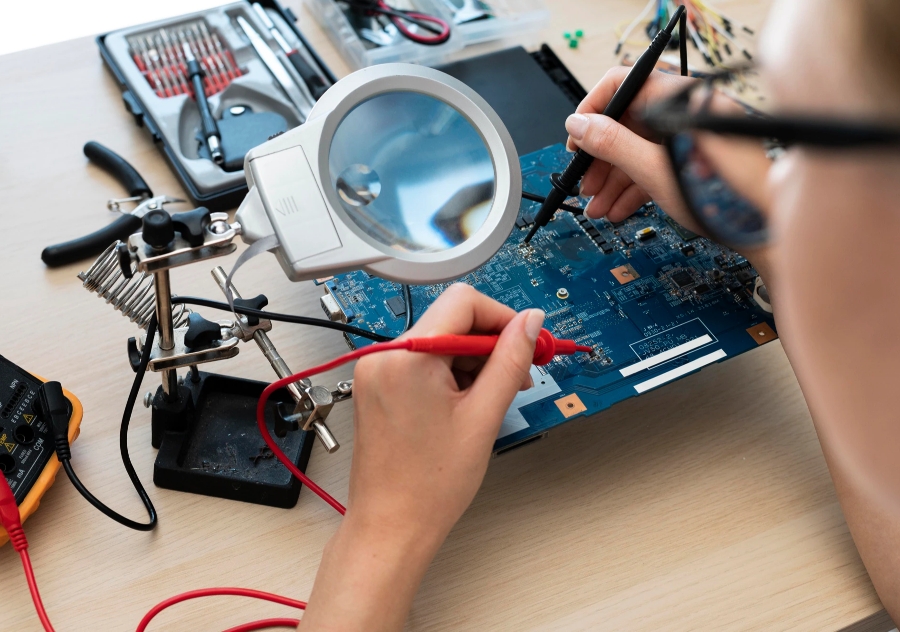

BGA Re-Work (Re-Balling)

- Altest BGA Re-Work system ensures that the most challenging requirements from the users are addressed with precision and process safety in electronic assembly rework applications.

- It contains a 1,800W high-performance Hybrid heating element which can be used to de-solder and solder SMT components.

- Maximum Package Size: 115mm x 115mm

Box Build

- Altest focuses on providing a solution to every manufacturing challenge.

- We offer box build assembly for any type of project. We can create custom enclosures for your PCBA project and send them directly to the consumers.

- We also maintain a clean, temperature-controlled warehouse to store all the finished products before shipment, along with our robust labelling and traceability software.

Cable / Harness Assembly

- Altest offers a wide variety of cable assembly types for all industrial applications. Our dedicated team of experienced and able engineers, design the cable and the assembly to provide a seamless end to end manufacturing process, for all the custom cabling works in our box build assembly projects.

- A harness is a group of wires and/or cables encased in a non-conductive durable sheath. Materials used for these coverings are typically rubber or vinyl due to their non-conductive properties. Gold, copper, aluminum, or many different metal alloys are used to make wires. Depending on the desired conductivity, we select the appropriate wires for our customers.