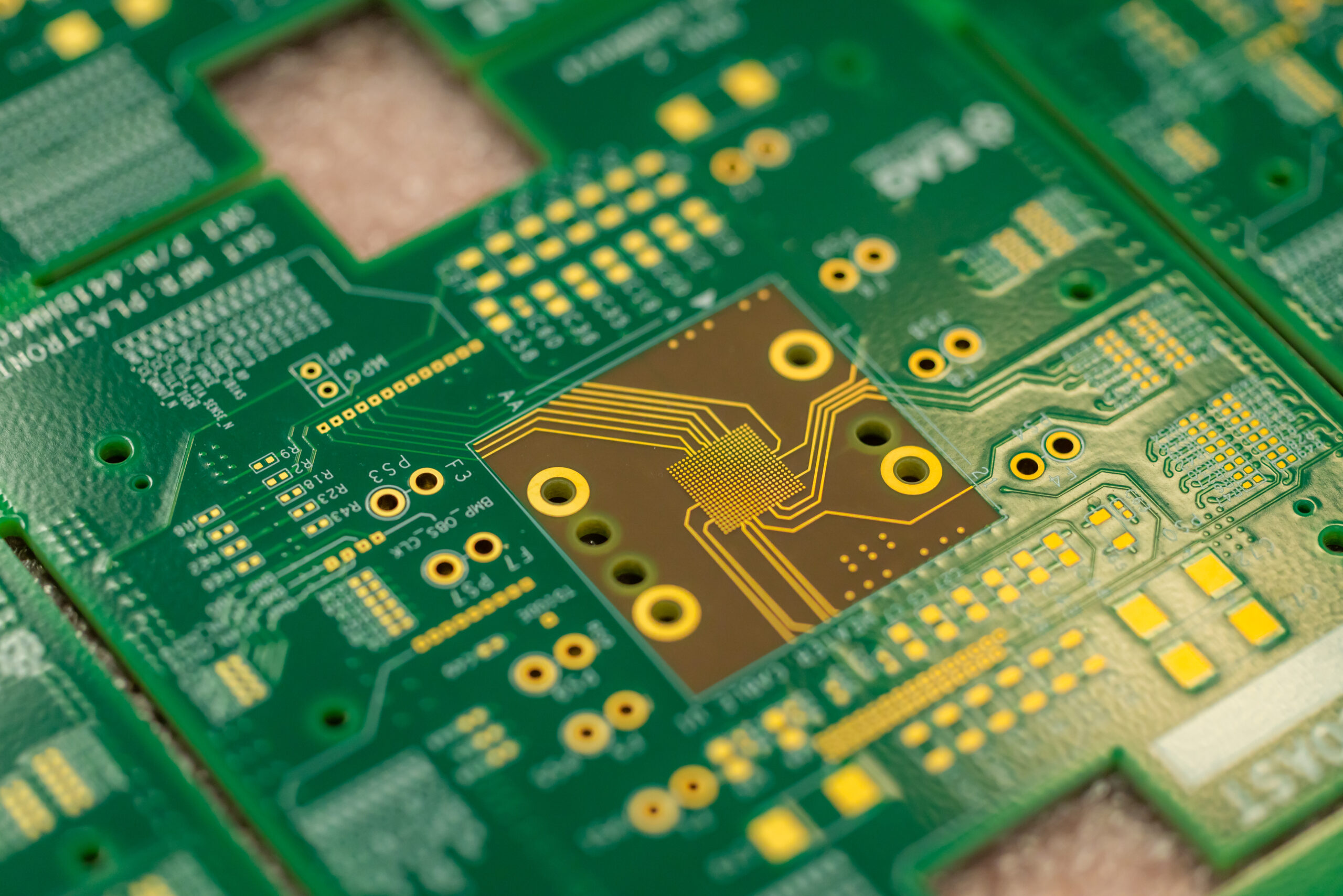

PCB Layout

Ensuring Electrical Performance Minimizing Signal Integrity Issues Thermal Management Manufacturability and Cost Efficiency

PCB Layout

PCB layout engineering requires careful consideration of several factors to ensure the final board meets performance, manufacturability, and reliability standards:

Component Placement:

Functionality: Components should be placed in a way that aligns with the signal flow, allowing for efficient routing and minimizing the distance between related components (e.g., capacitors near power pins, components with high-frequency signals close together).

Accessibility: Components that need regular maintenance or testing should be easy to access on the board.

Thermal Considerations: Components that generate heat, such as power transistors or voltage regulators, should be placed in areas with sufficient space or near heat sinks to ensure proper heat dissipation.

Routing:

Signal Traces: Signal traces should be as short and direct as possible to minimize resistance, inductance, and capacitance, which can degrade signal quality. High-frequency signals, in particular, require careful routing to avoid interference.

Trace Width and Spacing: Proper trace width and spacing are critical for both electrical performance and manufacturability. Trace width must be sufficient to handle the expected current without overheating, while spacing ensures that there is no short circuit between traces.

Industries We Serve:

How It Works

Consultation & Requirements

Discuss your project goals, requirements, and timelines with our team of experts.

Custom PCB Design Proposal

Receive a detailed proposal that outlines the design process, milestones, and cost estimates.

Design & Development

We bring your concept to life, ensuring the design meets your specifications and industry standards.

Review & Approval

Get a comprehensive design review and make any necessary adjustments before finalizing.

Prototype & Testing

Receive a fully functional PCB prototype for testing and evaluation.

Production Ready

Once validated, your PCB is ready for mass production.

Our Advantages

- Professional Design Team

- One-Stop Solution

- Rapid Design Delivery

- Manufacturing Advantage

Our PCB design team consists of experienced engineers who are proficient in design and layout in circuits as well as the best practices of manufacturing and are familiar with a variety of commonly used design software.

We provide one-stop solution services, covering the entire process from concept to final PCB design and product production. This includes shell design, hardware development, software programming, product testing and more.

Our powerful design capability ensures the shortest possible time on PCB design. For some projects, we can complete your requirements in as little as 24 hours.

Once the design is complete, we can directly proceed with production at our factory, helping you save a lot of time. Our manufacturing services include 3D&CNC, PCB and assembly